Brewhouses – 3 Tank

- Milling System 300-500Kg/h

- 10BBL-2 Vessel Brewhouse System (MLT&KWT)

- 20BBL Hot Water System

- 10BBL Fermentation Tank/Unitank (Side man hole with Carbonation device)

- 10BBL Bright beer Tank/Unitank (Side man hole with Carbonation device)

- Cooling Liquor System (30BBL Cold liquor tank +10HP Chiller )

- 100L CIP System

- Digital Control System with separate control cabinets for the brewhouse and for the fermentation and bright beer tanks

- Description

Description

Description

Grain mill

- Capacity: 300-500Kg/h

- Motor power: 1.5KW

- Type: Double Alloy Rollers

- Rotational Speed: 800rpm

- Noise<60db

- Adjustable rollers

- Temperature of Rollers after Production: ≤56℃

- Shell Material : Stainless steel

Mash Tun/Lauter Tank

- Total capacity:15BBL.

- Useful capacity:10BBL.

- Outline size:φ1560×2300mm. φ5.12*7.55 ft

- Interior Shell:SUS304 Stainless Steel,thickness: 4.0mm;

- Exterior Shell:SUS304 Stainless Steel,thickness: 2.0mm;

- 100% TIG welding with pure argon gas shield

- Interior Finish: Overall polishing to 0.4~0.6 μm without dead corner

- Insulation:Polyurethane-thickness:80mm.

- Top agitator system with frequency control speed motor and turbine reducer, Power: Lauter Tank

- Vessel light assembly

- Glass top mounted manway

- Heating way: Steam heating

- Steam safety device:Pressure gauge,safety valve,globe valve

- Steam Jacket: Dimple plate on bottom and side,thickness:3mm

- Mashing Temperature:1.2℃/min

- Angle seat pneumatic valve for steam flow, automatic temperature control.

- Side grain outdoor with grain chute

- Spent grain removal way : Reversal spend grain discharge

- Laser cutting V-wire False Bottom/Sieve plate,easy detach to clean Plate thickness 4mm ,gap:0.7 mm, form:Strip-shaped holes

- Flat base With Backflush washer device and wort collection loop .

- 360° coverage CIP spraying ball,two pieces

- Easyclean and detachable sparging spray ring

- Thermowell with high accuracy temperature sensor: PT100.

- Equip with adjusting anchor; 4 support legs add braced.

Note: Inner tank inside surface fully acid washed and passivated after polishing. Form protective film, easy to clean, no sanitary dead angle.

Brew Kettle/Whirlpool Tank

- Total capacity:15BBL.

- Useful capacity:10BBL.

- Outline size:φ1560×2300mm. φ5.12*7.55 ft

- Interior Shell:SUS304 Stainless Steel,thickness: 4.0mm;

- Exterior Shell:SUS304 Stainless Steel,thickness: 2.0mm;

- 100% TIG welding with pure argon gas shield

- Interior Finish: Overall polishing to 0.4~0.6 μm without dead corner

- Insulation:Polyurethane-thickness:80mm.

- Glass top mounted manway

- Heating way: Steam heating

- Steam safety device:Pressure gauge,safety valve,globe valve

- Angle seat pneumatic valve for steam flow, automatic temperature control.

- Steam Jacket: Dimple plate on bottom and side,thickness:3mm

- Equipment with tangent tube

- Vessel light assembly

- 360° coverage CIP spraying ball,two pieces

- Thermowell with high accuracy temperature sensor: PT100

- Equip with adjusting anchor; 4 support legs add braced.

Note: Inner tank inside surface fully acid washed and passivated after polishing. Form protective film, easy to clean, no sanitary dead angle.

Buffer Tank

Hop Back

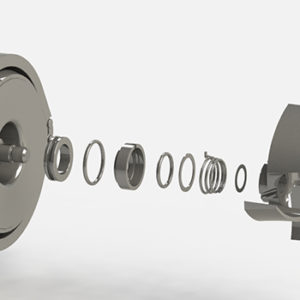

Wort Pump

- Food grade centrifugal pump.

- Capacity:5m3/h, Power: 1.5KW,lift:24m; Wort pump

- Controlled by variable frequency drives (VFD’s).

- Wort pump with open impeller, outside system seal

- Pump shaft position: horizontal type

Work Platform

- Completely stainless steel setup

- Non slip metal floor

- Integrated stairs or ladder Work Platform

- Solid and ground hand rail

- Every weld to a smooth sanitary finish

Plate Heat Exchanger

- Two stages for glycol water and cold water

- Completely 304 SUS Corrugated plates

- Full detachable for regular thorough cleaning

- Thermometer for wort outlet temperature controlling

- Effective Cooling Area: 10M2 Plate heat

- Design/Test Pressure: 10bar/13bar exchange

- Working Temperature: <150℃

- 40 Minustes coolling wort to the fermentation temperature.

- City water, alcohol water, wort inlet and outlet

- Brand : Shanghai Nanhua

Venturi Wort Oxygenation

- Combine oxygenator and temperature gauge Venturi Wort

- Including sight glass Oxygenate

- Sanitary wort aeration mounted with carbonation stone Assembly

- The amount of oxygen is adjustable

- Range of temperature measuring: 0-100℃

Yeast Addition Tank

- Yeast Hold Volume: 12L

- Material: Sanitary SUS304 full welded, Single wall tank,thickness:2.0mm

- Completely draining sloped bottom

- Tri clamp aeration port with ball valve

- Discharge arm with butterfly valve

- Connection type: quick installation, with the wort oxygenation combined.